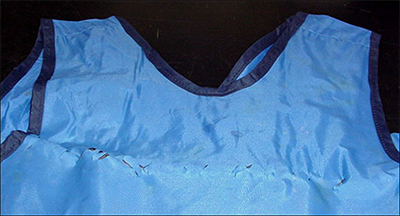

When leaded Personal Protective Equipment (PPE), such as leaded aprons, thyroid collars, skirts, vests, or gloves are not handled and stored properly, they can develop tears in the fabric; as a result, the person wearing that PPE will be exposed to ionizing radiation. To prevent this, never fold lead aprons. When storing lead PPE, always hang it up or lay it flat.

When leaded Personal Protective Equipment (PPE), such as leaded aprons, thyroid collars, skirts, vests, or gloves are not handled and stored properly, they can develop tears in the fabric; as a result, the person wearing that PPE will be exposed to ionizing radiation. To prevent this, never fold lead aprons. When storing lead PPE, always hang it up or lay it flat.

The Tennessee Department of Health and Environment, Division of Radiological Health requires annual inspection of lead shielding used as PPE. Lead shielding PPE inspections are also a high priority with The Joint Commission, and in areas where lead aprons are used, Environment of Care survey teams check to verify that leaded PPE have been inspected within the last year.

Inspections

The Department of Radiology performs annual lead shielding inspections following local SOP guidelines established by each facility. Inspections include inventory tracking and maintenance of an inspection history record for each item. New leaded PPE must be inventoried and inspected before use. Please coordinate inspection with Radiology immediately upon arrival of new leaded PPE.

Tagging System

A vinyl compliance “year" disc attached to an orange “VANDERBILT” tag indicates the year of the most current inspection.

A vinyl compliance “year" disc attached to an orange “VANDERBILT” tag indicates the year of the most current inspection.

In addition, each piece of leaded PPE has a SmartID label with a QR Code. Scanning the QR code with a smart phone will show the date of the last inspection for that piece of leaded PPE. If the date shown is within the year, then that protective garment meets requirements for use.

If a piece of leaded PPE does not have a vinyl compliance year disc or SmartID label attached, or for any other questions regarding the lead inspection program, please contact the Department of Radiology at your facility.