ELECTRICAL HAZARDS

Electrical cords should be inspected for damage before plugging the laser unit to the power outlet. Solution bottles and bowls should not be placed on top of the laser unit because any spillage or splatter could cause internal short circuiting within the laser. Protective housing of the laser unit should never be opened or removed by unauthorized staff. Laser foot pedals should be kept dry from irrigations and other solutions used during the laser procedure.

Some lasers units use high-voltage power supplies, large capacitors, or capacitor banks that present a lethal shock hazard. Electrical safety controls include:

- OSHA [29 CFR 1910 S] requires additional controls and training for work on live circuits operating a more than 50 volts; Capacitors maintain a lethal charge even if the equipment

- is de-energized and unplugged.

- Observe extreme caution when servicing laser equipment

- Check laser unit for frayed wires and ensure that electrical terminals are covered.

- Only use laser unit with current preventive maintenance tags or stickers

- Use specified power outlets for specific laser unit or per manufacturer recommendations

- Use equipment only for its intended/designed purpose.

Good judgment and generally recognized electrical precautions

should be observed around all laser equipment.

LASER GENERATED AIRBORNE CONTAMINANTS (LGAC)

Laser Generated Airborne Contaminant can contain blood, blood by-products and pathogens. Laser procedures that produce plume shall use control measures such as portable smoke evacuators or the local exhaust ventilation. Laser plume is a health hazard. Irritation by laser plume can cause burning, watery eyes, nausea and vomiting, and headaches.

As the plume wand is held within 1 cm of the laser impact site, approximately 98% of the smoke is eliminated. As the wand is held 2 cm away, the evacuation of the plume is decreases to 51%. (Milhashi S et al: Some problems about condensates induced by CO2 laser irradiation, Department of Otolaryngology and public health, 1975b, Karume university)

FIRE

- Dry combustibles should never be placed in the immediate vicinity of the laser target area. Potentially flammable items, such as towels, sponges, gauge pads, and swabs should be wet so that ignition cannot occur. Use fire-retardant drapes, damp pack or pads

- Never use alcohol or flammable agents in the operating field.

- Fibers may be rinsed in hydrogen peroxide, water, or saline intraoperatively.

- Never place a hot fiber directly on dry drapes. Wait until tip is cool before contact is made with flammable materials

- Put laser system on standby mode when procedure is interrupted or terminated

- Avoid high levels of oxygen in the operative field.

- Avoid laser beam exposure of the sheaths of flexible fiber endoscopes.

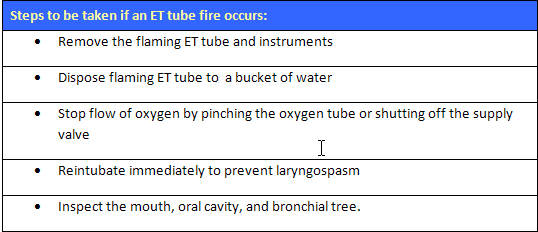

- Use laser wavelength specific endo-tracheal tubes for laser procedures involving the respiratory tract.

COMPRESSED GASES AND CRYOGENICS

Hazardous gases may be used in laser applications; i.e. excimer lasers (fluorine, hydrogenchloride). Cryogenic fluids are used in cooling systems of some lasers. The SOP should contain references for the safe handling of compressed gases. Refer to MSDS for detailed information on the safe handling on the specific compressed gas and/or cryogenic used with the laser unit.

DYES

Dyes used as the optically active medium in some laser units are toxic and/or carcinogenic chemicals dissolved in flammable solvents. This creates the potential for personnel exposures above permissible limits, fires, and chemical spills. Refer to MSDS for detailed information on the safe handling on the specific dyes used with the laser unit.

UV AND VISIBLE RADIATION

Maintaining the integrity of the laser housing and avoid operating any laser unit without the protective housing will provide protection from UV and visible radiation that pose eye and skin hazards.